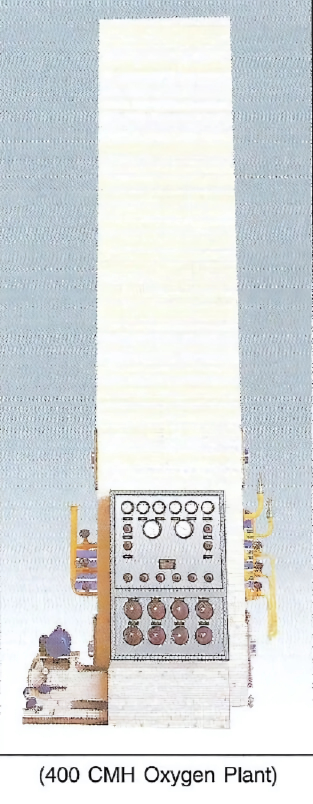

Sanghi Oxygen Plant

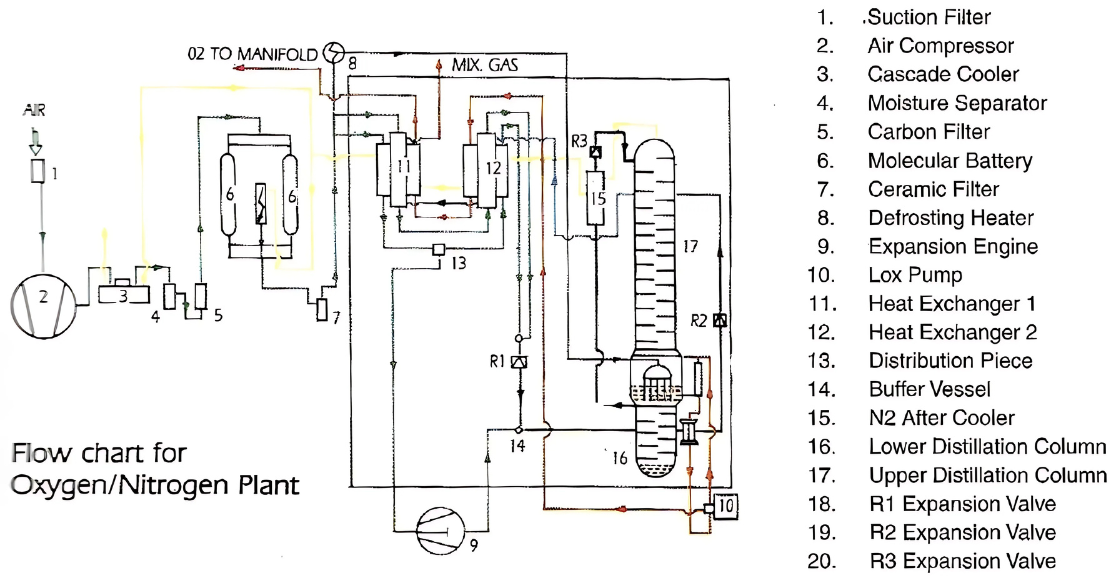

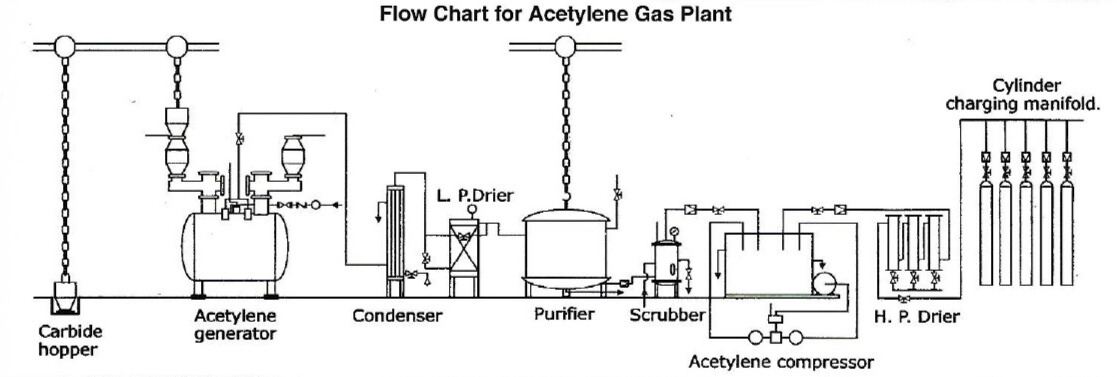

Process Description :

The free atmospheric air is sucked in by a multi-stage air compressor through a filter and compressed to the working pressure. The compressed air then passes through the cascade cooler and then to the molecular sieve battery where the moisture and carbon dioxide are removed from the process air. It then passes through exchanger No.1 where it is cooled by the outgoing waste nitrogen and product oxygen. Apart from this cold air then flows through an expansion machine and the balance through the 2nd heat exchanger. An expansion valve, R1 Both these streams of air then unite in the lower pressure column where it partially liquefies, controls the ratio of the two air streams. The liquid air (rich air) then passes through the expansion valve R2 to the upper column, which is at a lower pressure than the lower column. Similarly, the liquid nitrogen (poor liquid) travels from the lower column to the upper column through an expansion valve R3 where the separation of oxygen and nitrogen occurs. Nitrogen is more volatile passes out as a gas from the top of the column and this waste nitrogen flows through both the heat exchangers cooling the incoming air. Similarly, product oxygen is also passed through the two heat exchangers to coll the in-coming air and then to the filling manifold via a liquid pump. If a small amount of air is vented out from the upper column, higher purity nitrogen can also b obtained from this plant. R4 Valve is provided in order to fasten cooling during start-up.

Salient features of Oxygen / Nitrogen plants :

- Leak Proof argon welded column

- Column available in Copper/Stainless Steel

- Very compact & sturdy oxygen and nitrogen plants

- Low working pressure Oxygen gas Plants

- Very low maintenance for producing oxygen gas

- Raw material -Free Atmosphere Air for producing Oxygen/Nitrogen gas/liquid

- Built-in Liquid Oxygen / Nitrogen pump with an internal gas vaporizer for filling of bone dry and high purity Oxygen/Nitrogen gas in cylinders

- Hydraulic type Expansion Engine for Oxygen/Nitrogen plants

- Highly efficient Heat-exchanger for recovery of waste cold energy to reduce operating cost

- The oxygen plant is supplied complete as per the standard scope of supply

Sanghi Oxygen Plant

Safe and economical, the sanghi Oxygen Plant, with an efficient Expansion Engine, lowers operating pressures to a remarkable 30 kg/cm2, cuts power consumption, and adds to safety.

sanghi Plants are supplied with a very efficient reciprocating four-stage Air Compressor, which consumes low power. Sanghi Plants are supplied with a specially designed highly efficient Cascade Cooler, which eliminates the need for chilling unit and saves on recurring maintenance and power cost.

A Molecular Sieve Battery brier unit for separation of moisture and carbon dioxide is another money-saving device in the SANGHI plant. It removes acetylene and other hydrocarbons from the process air, thus eliminating the need for separate acetylene absorbs, and moreover it eliminates recurring caustic soda costs.

Capable of simultaneously producing oxygen and High purity nitrogen, the SANGHI plant has an internal compression Liquid Oxygen Pump to fill dry gaseous oxygen in cylinders. The plant can also be fitted with a separate liquid Nitrogen pump to fill dry Nitrogen directly into cylinders. Plants to produce liquid Oxygen/ Nitrogen can also be offered. We also undertake supervision of installation and commissioning of the plant.

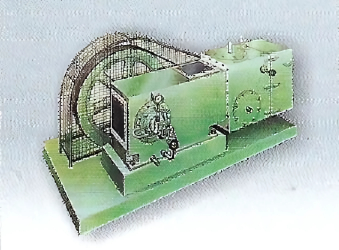

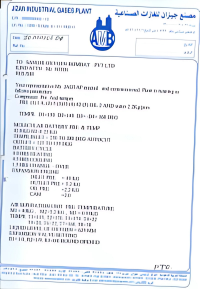

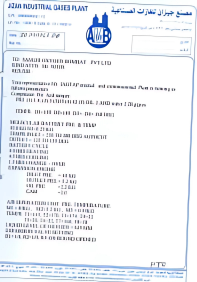

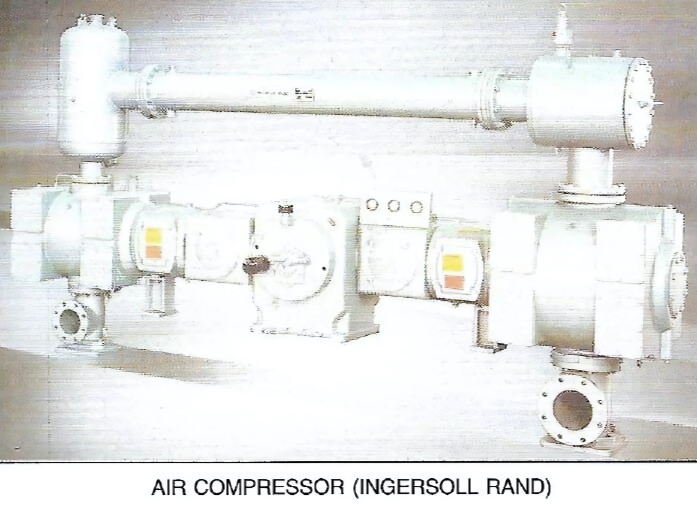

Air Compressor

Air Compressor – Type – Reciprocating, Horizontal, Balance opposed, water-jacketed, 3 / 4 / 5 stages, depending upon operation cycle. The air compressor is complete with interstage coolers, separators, motor starter.

Skid Mounted Air Compressor

SKID Mounted Air Compressor can be offered on request.

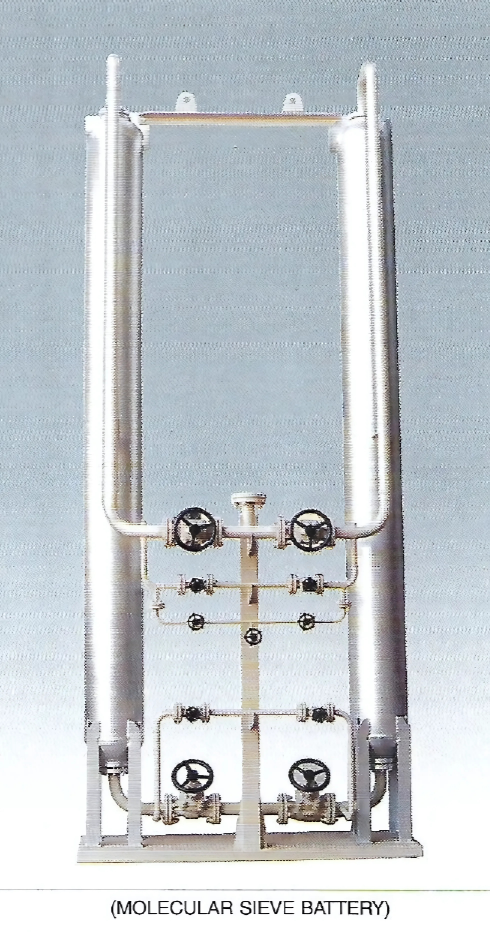

Molecular Sieve Battery

This is a battery of two vessels filled with Molecular Sieve type 13-X to absorb Carbon Dioxide and Moisture from process air. One vessel will be online and the other will be regenerated by Dry Nitrogen. Regeneration Heater also provided.

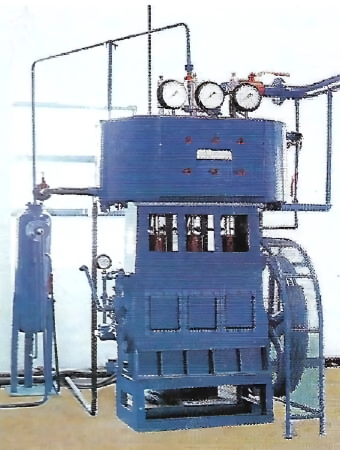

Expansion Engine

Expansion Engine is a vertical reciprocating machine which can expand air adiabatically from operating air pressure to 5Kg/cm2 o produce the required cold for the Oxygen / Nitrogen plant. It greatly helps to reduce power consumption.

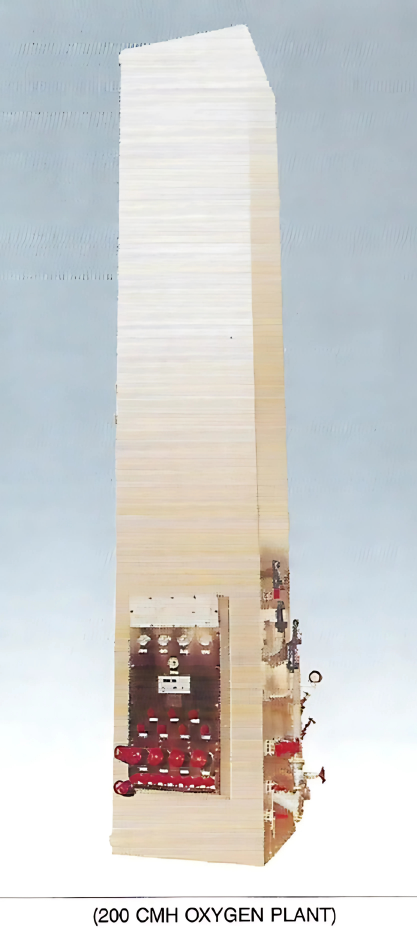

Air Sepration Unit/Cold Box

Air Separation Unit/Cold Box consists of Distillation Column with Heat Exchangers for heat transfer between the incoming air and the outgoing cold Nitrogen and Oxygen. It is equipped with Expansion valves for controlling the operation of the plant. The Control panel for the cold box is provided with the plant. Defrost heater for the thawing plant is also provided on the cold box. It is also equipped with a liquid oxygen pump which is single cylinder equipment and delivers Bone-dry Oxygen up to pressure 165Kg/Cm2. The cold box is insulated with perlite for minimizing cold losses and reducing power consumption.

Oxygen / Nitrogen Liquid Pump

The liquid Pump is a horizontal reciprocating pump. It can pump cryogenic liquids such as Liquid Oxygen, Nitrogen, and Argon up to 165Kgm/Cm2 pressure normally and 250 Kgm / Cm2 pressure in special cases. the pumps are simple and require the least maintenance.